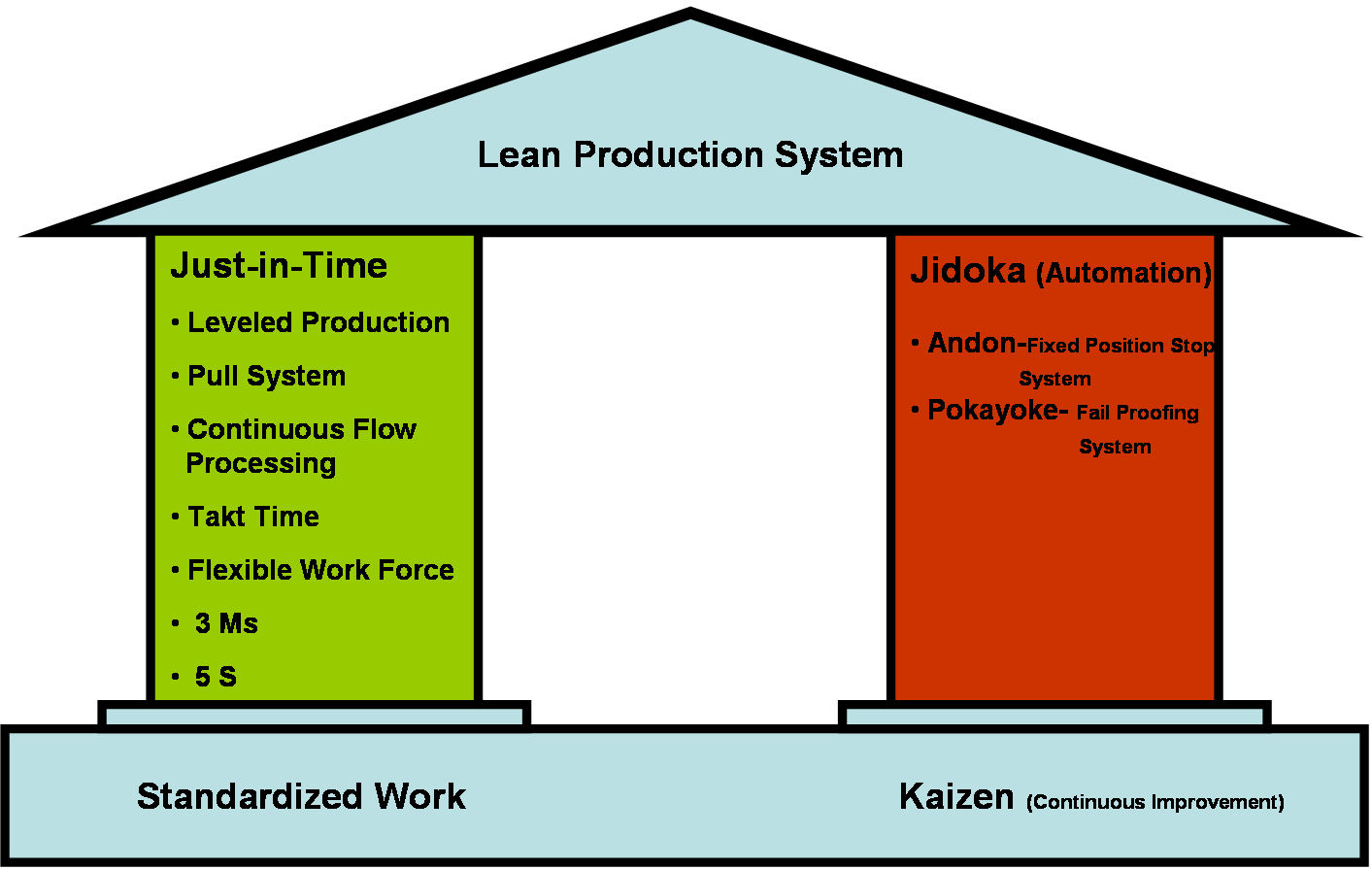

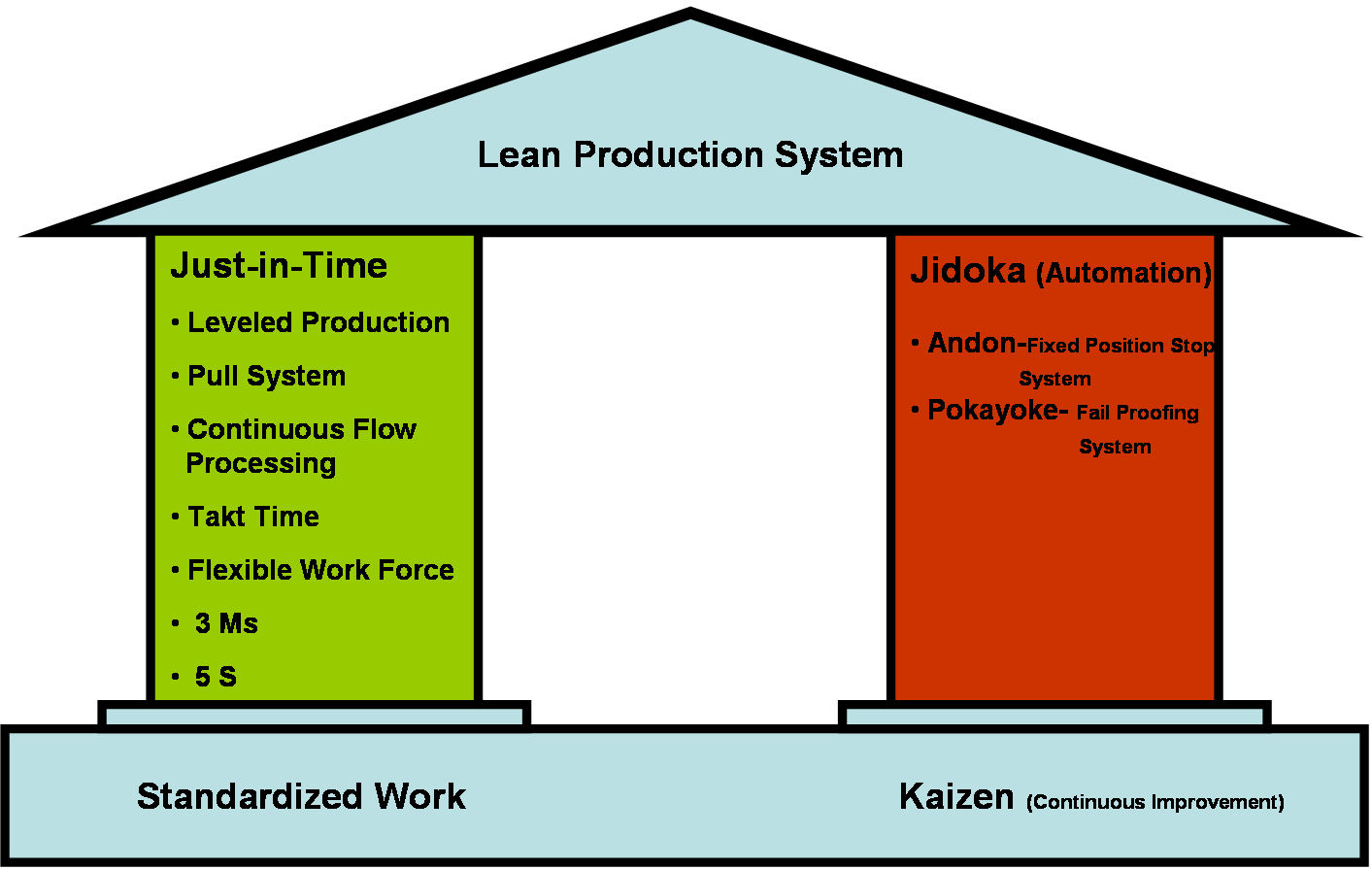

Creation of safety environment and ensuring total quality management.Like all good revolutions, just-in-time manufacturing is producing revolutionaries who don’t know when to stop.Simplification and advancement of the existing systems.Elimination of non-value added activities and procedures.Continuous improvement of production and order processing.With the above fundamentals in place, JIT delivers the following: JIT is based on the following fundamentals: JIT as philosophy is applicable to various types of organization but on implement side it is more relevant with manufacturing operations.įor JIT system to be successful, there are two critical elements, attitude of workers/management and practice. Just In Time is set of strategic activities, which are formulated to achieve maximum production with minimal maintenance of inventory. Inventory management ensures that organizations are able to minimize cost and maximize profit. They include clean- up cost, re-tooling cost and adjustment cost.

Set Up Cost are cost associated with installation of machine for production. They include forms, order processing, office maintenance supplies and staff associated with ordering. Ordering costs are cost associated with purchasing of raw material and receiving raw materials. They include insurance, warehousing, interest, extra head-count, etc. Holding costs are carrying cost associated with inventory over a period of time. There are three broad categories of cost associated with inventory holding cost, ordering cost and set up cost. For example, demand for raw material can be established as the basis of demand of finished products. Dependent Demand Inventory Model talks about raw material demand which are integral parts of production and form important part of material resource planning. Finished goods is an appropriate example for independent demand inventory model. Independent Demand Inventory Model talks about raw material demand which is dependent upon prevailing market conditions and is not correlated to any raw material currently used by the organization. Inventory management is based upon two basic models i.e independent demand inventory model and dependent demand inventory model. Inventory decision involves two major considerations, first is the order quantity of the raw material and second is timing for placing those orders. It ensures that any delay by suppliers do not affect working of the company.Ĭonsidering the above inventory holding objectives, next step for the company is to make inventory related decision. It ensures that there is flexibility in production. It also ensures that company can meet spikes or fluctuation in product demand.

Set Up Cost are cost associated with installation of machine for production. They include forms, order processing, office maintenance supplies and staff associated with ordering. Ordering costs are cost associated with purchasing of raw material and receiving raw materials. They include insurance, warehousing, interest, extra head-count, etc. Holding costs are carrying cost associated with inventory over a period of time. There are three broad categories of cost associated with inventory holding cost, ordering cost and set up cost. For example, demand for raw material can be established as the basis of demand of finished products. Dependent Demand Inventory Model talks about raw material demand which are integral parts of production and form important part of material resource planning. Finished goods is an appropriate example for independent demand inventory model. Independent Demand Inventory Model talks about raw material demand which is dependent upon prevailing market conditions and is not correlated to any raw material currently used by the organization. Inventory management is based upon two basic models i.e independent demand inventory model and dependent demand inventory model. Inventory decision involves two major considerations, first is the order quantity of the raw material and second is timing for placing those orders. It ensures that any delay by suppliers do not affect working of the company.Ĭonsidering the above inventory holding objectives, next step for the company is to make inventory related decision. It ensures that there is flexibility in production. It also ensures that company can meet spikes or fluctuation in product demand.

Inventory holding ensures that operation delay do not impact delivery to customers.Inventory Holdingįor an organization, it becomes important to hold inventory for the following reason: Therefore, it is important to have a robust inventory management for an organization. Also there are chances that stored inventory may get damaged or get stolen adding to extra cost to the company. Inventory involves various cost, investment, space management, etc. Within supply-chain management, inventory management plays a central role. Supply-chain management plays a pivotal role in ensuring goods, and services are delivered on time to customers.

0 kommentar(er)

0 kommentar(er)